You may think it’s strange for an organization that works primarily in the digital space to make a big deal about physical prototyping. You wouldn’t be the first to think this. It’s true, clients don’t hire us to build cars, speakers, or clothing, but the stuff we are hired to do (mobile apps, design strategy, software development, etc.) are still used out there in the physical world.

Why prototype?

Prototypes are artifacts that we can use in the process of creating things. We use them for ideation, exploration, and communication in design. They help us simulate, test, and refine ideas before implementation. They can be created along the entire process of designing and making, and their form varies based on the intended purpose.

At Cantina, we believe physical prototyping is a great approach to solving problems, whether your product is digital or physical. Prototypes can reduce time and cost to create things by giving us options for fidelity and scale. They help to figure out if what is being built fits the need and help to explain ideas through storytelling.

A great example is SIMPeds at Boston Children’s Hospital. They are prototyping at scale to simulate a wide range of activities from procedural training, to space and facilities design. They use simple tools like cardboard for walls to create the environment and high-tech devices like 3D printing to achieve real-life simulation.

The structure of a prototyping workshop is what makes it so successful and productive, but within that format there are moments of uncertainty and doubt. It’s during those times when the unexpected happens and challenges are solved.

Free Prototyping Guide

Let our guide help you speed up the process, reduce cost, and design and build the right thing.

Before you begin

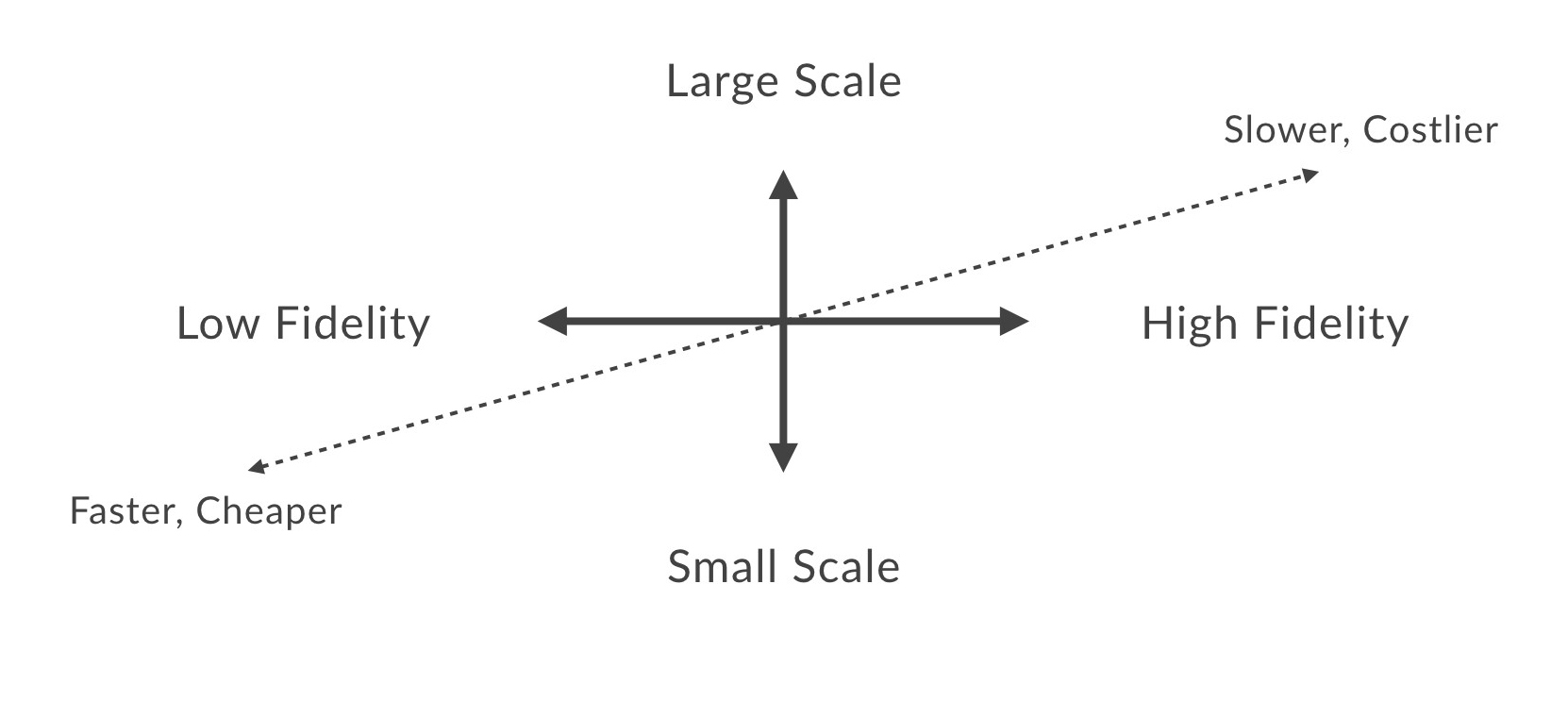

Prototypes can be done at varying levels of scale and fidelity: physical or digital. In all cases, they need to answer one or more questions about the design of a thing, either through their own form or through the process of simulation.

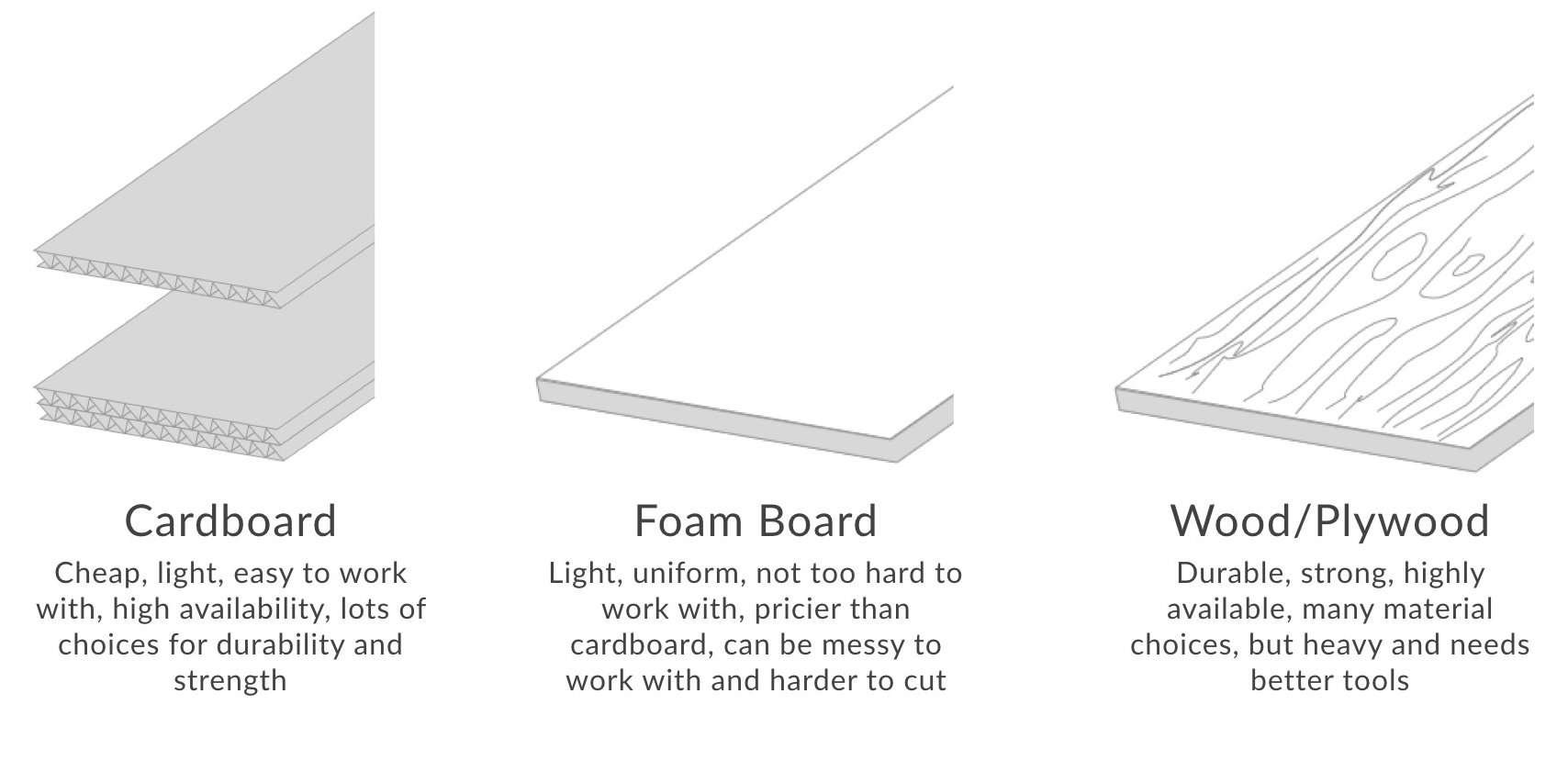

There are lots of great materials when prototyping at full, life-size scale. There are several “off the shelf” materials that work well: cardboard, foam board, wood, and plywood are all fairly easy to get and work with, but we recommend cardboard because it’s cheap, easy to cut and fold, and most offices have a stack of boxes laying around.

Our Prototyping Services

Increasingly businesses are adopting prototyping to solve all kinds of user experience challenges both offline and online. At Cantina, we help organizations use the fundamentals of prototyping to design, build, and validate ideas before deciding to build something. We do this by:

- Facilitating workshops to better understand problems

- Strategizing how digital products and services may solve the problems

- Designing and building prototypes to experiment, learn, and validate assumptions

- Empowering teams to build smarter business cases backed by evidence

Drop us a line if you think prototyping could help to get your product get off the ground.